Sigma

Enterprise-grade manufacturing management system for the custom supplement sector.

The Opportunity

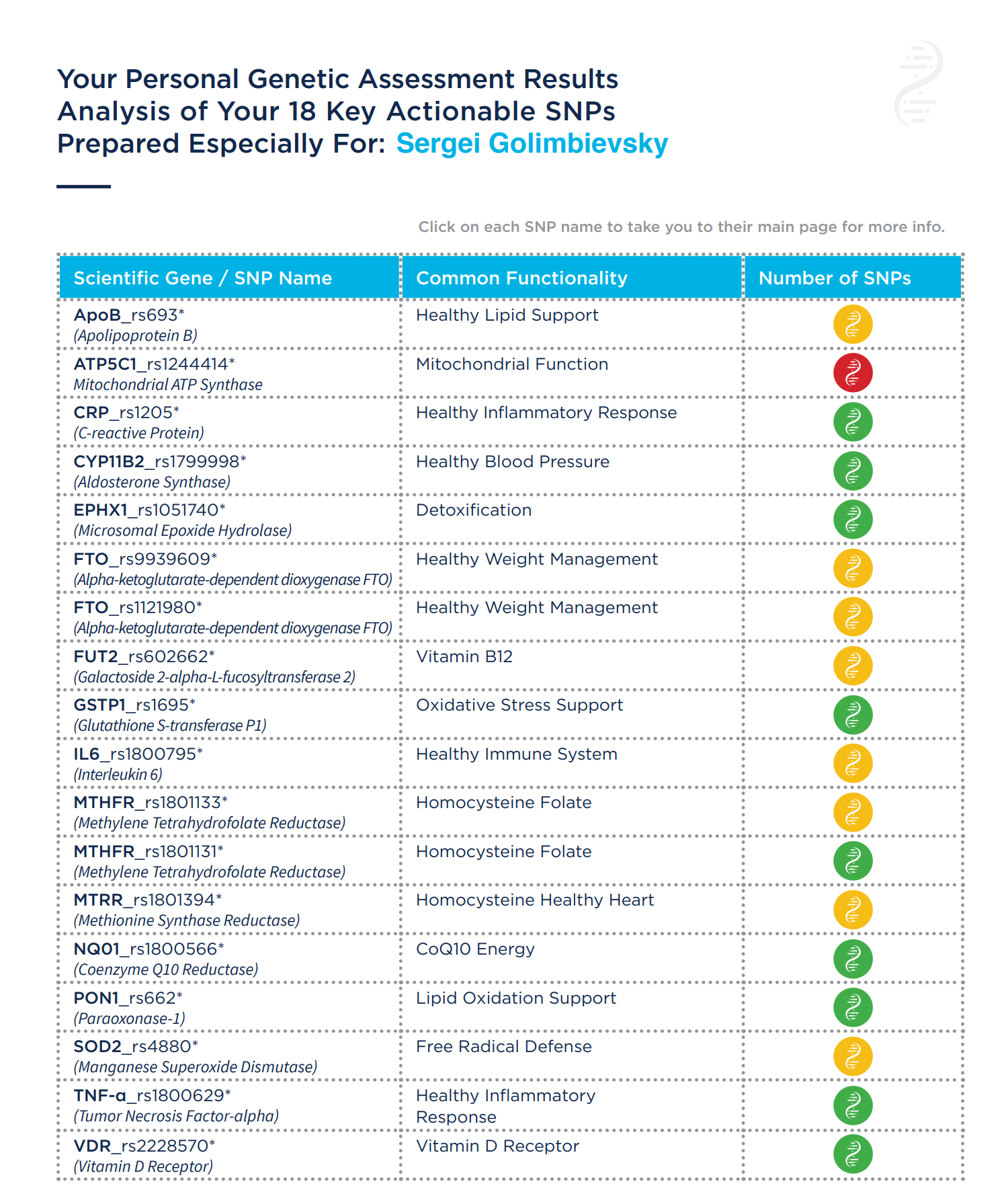

LaCore Nutraceuticals, a prominent player in the health products manufacturing industry, recognized the potential to revolutionize their offerings by integrating personalized health solutions. The advent of precision medicine and the increasing demand for customized health products presented LaCore with the unique opportunity to expand their product line to include custom formulations based on individual DNA analysis. This strategic pivot aimed to position LaCore at the forefront of the health industry, transforming how consumers approach wellness and health management.

The Challenge

The transition to producing DNA-based custom health products required a sophisticated management system capable of handling complex and sensitive data. LaCore Nutraceuticals faced multiple challenges in managing intricate processes such as customer orders, ingredient tracking, recipe formulations, and the integration of DNA sample results. Each aspect needed seamless synchronization to ensure accurate production and inventory management. Moreover, the handling of personal genetic information demanded stringent data security and compliance with health regulations, adding layers of complexity to the project.

The Solution

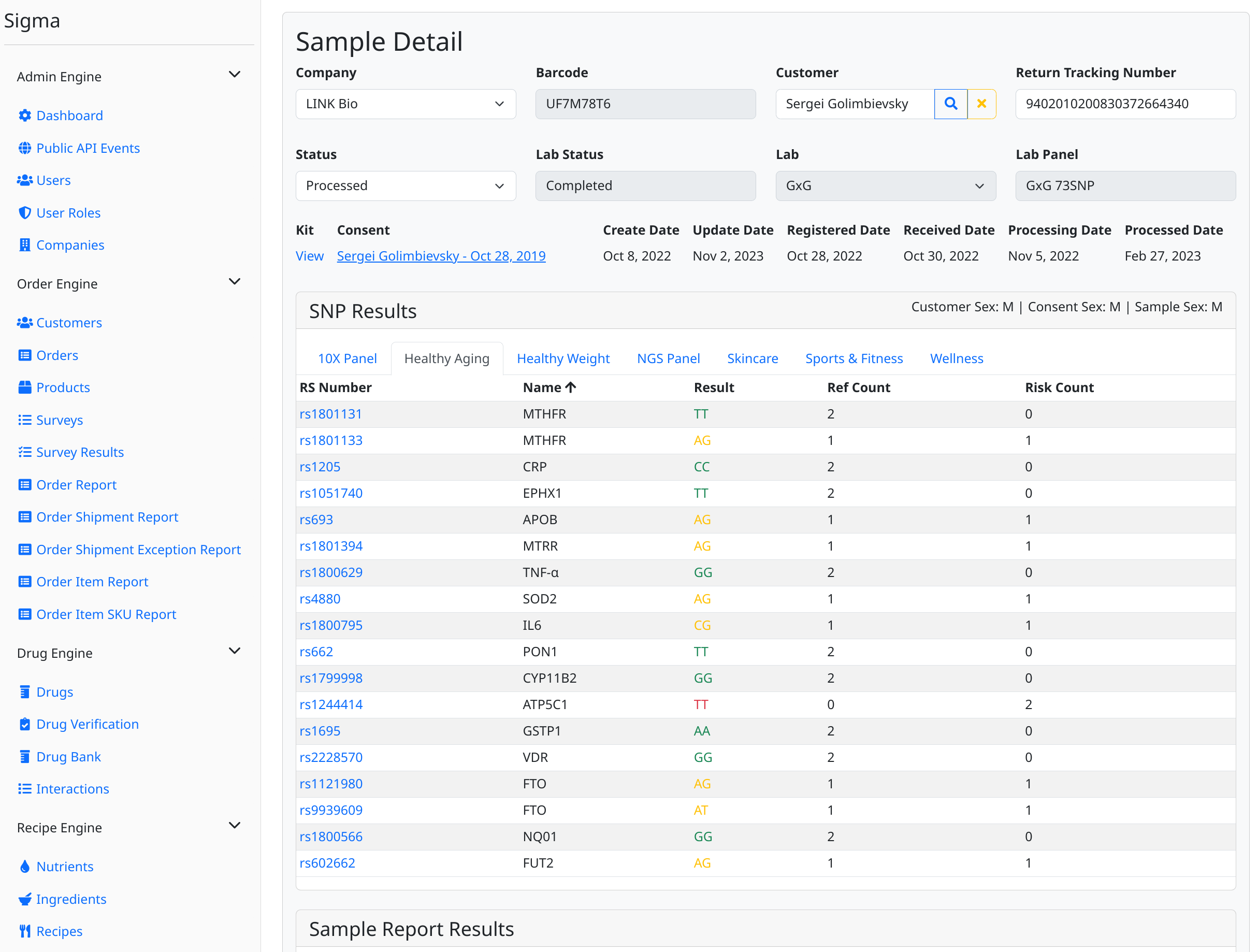

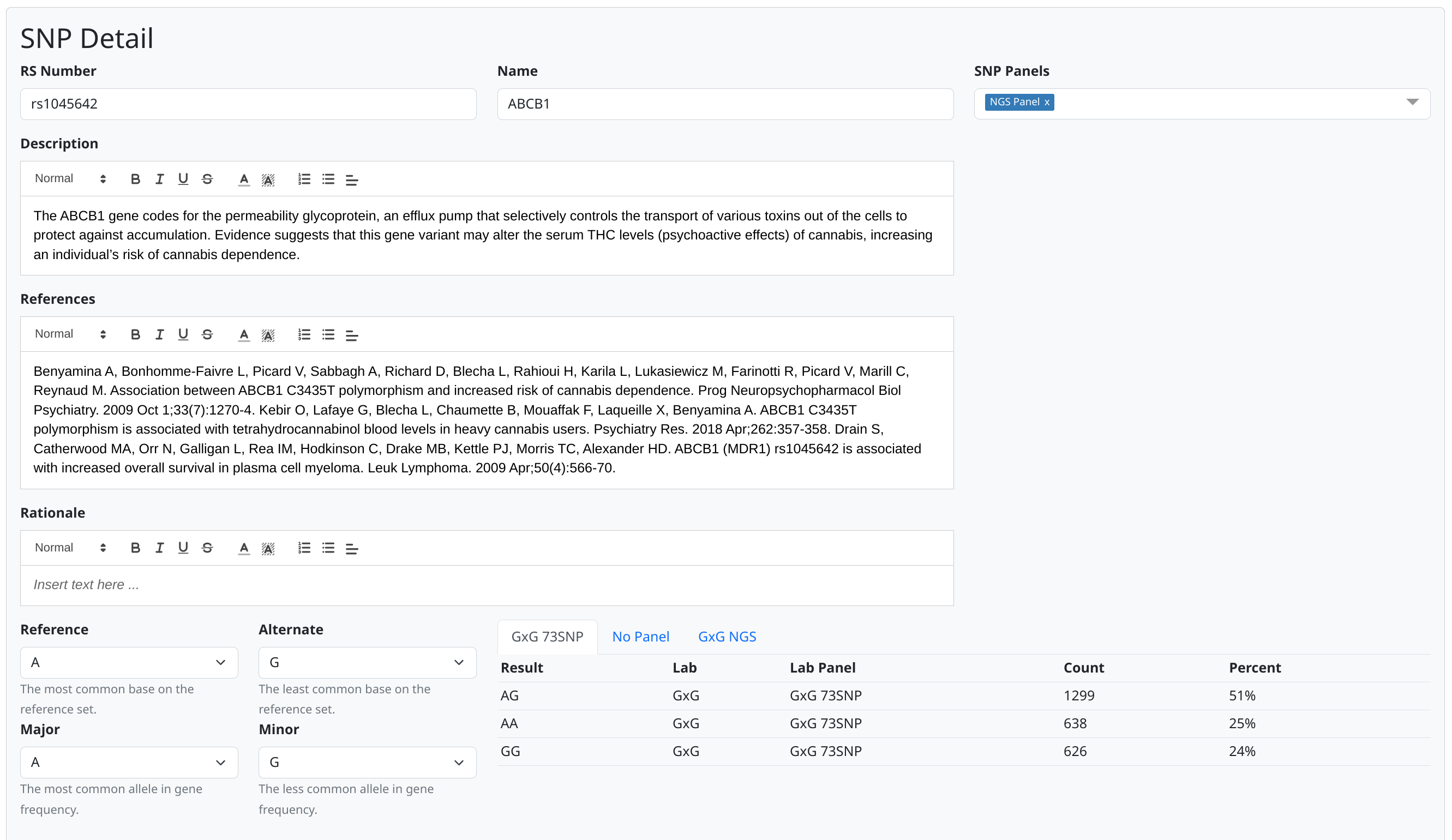

To address these challenges, we developed Sigma, a comprehensive manufacturing management system tailored to LaCore Nutraceuticals’ specific needs. Sigma seamlessly integrates various facets of the manufacturing process—from customer orders and DNA result integration to inventory management and batch production records. The system was designed with robust security measures to ensure the protection of sensitive genetic data and compliance with regulatory standards. By automating and streamlining operations, Sigma enabled LaCore to efficiently manage their innovative product line, ultimately enhancing production capabilities and enabling a successful pivot to DNA-based product customization.

Technologies Used

To build and support Sigma, we utilized a robust stack of modern technologies. The backend operations are powered by NestJS, offering a scalable framework for building efficient server-side applications. For the database, we employed MongoDB, which provides the flexibility needed to handle the complex and varied data structures inherent in DNA-based product customization. The client-facing elements were developed using Angular, ensuring a responsive and intuitive user interface. Additionally, the entire system is hosted on AWS, providing reliable and secure cloud services that enhance system performance and scalability.